| Material | Galvanized/ Aluzinc steel coil (Galvalume Coils)/ Aluminum Coils /SGCC/ DX51D-Z/ AZ |

| Thickness | 0.14mm~1.2mm |

| Width | ≤1250mm |

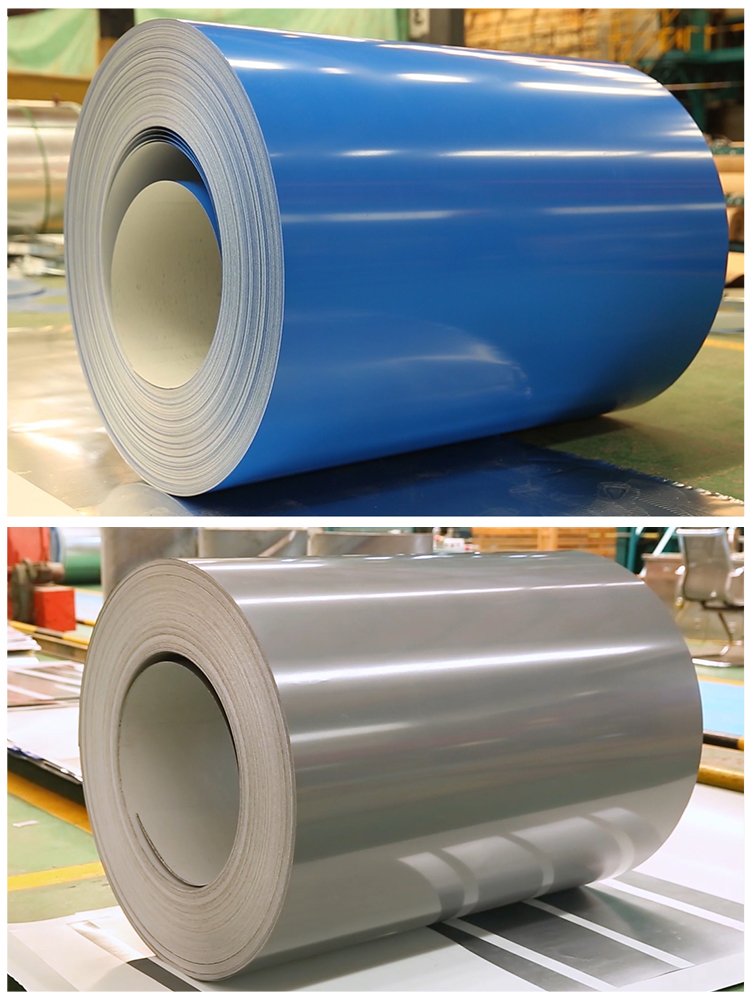

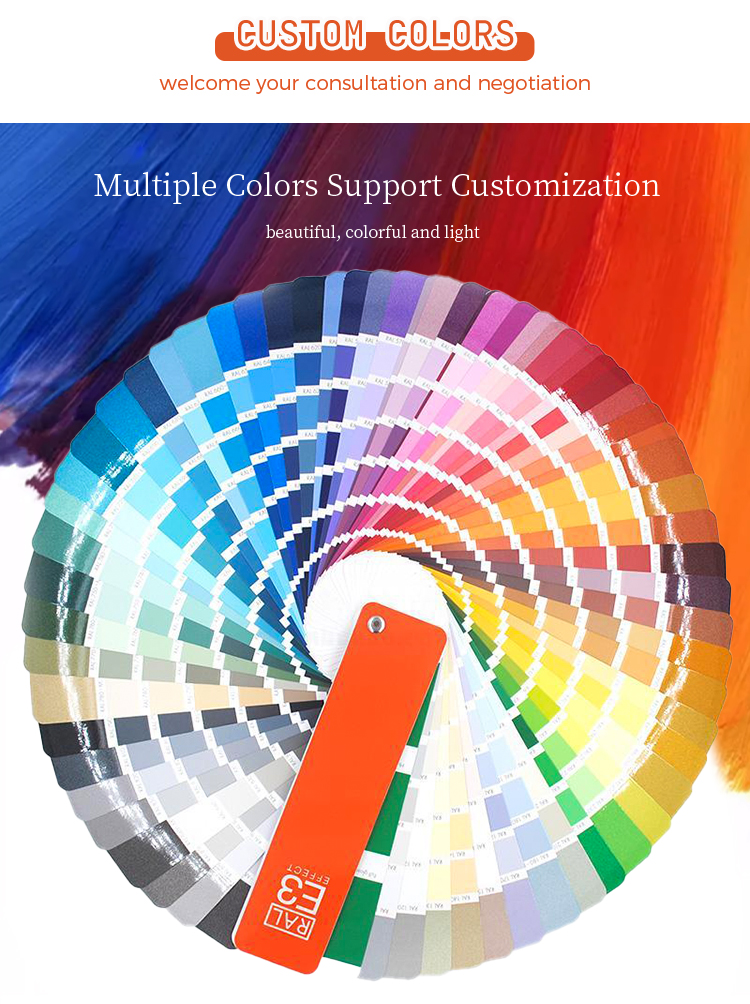

| Color | Red/ blue/ white or any other RAL color |

| Hardness | 50HRB to 90HRB |

| Top/ Back Coating | 12μm to 25μm/ 5μm to 10μm |

Color coated coil has good durability, corrosion resistance and longer service life compared with galvanized steel plate;

It has good heat resistance and is not easy to change color at high temperature compared with galvanized steel plate;

It has good performance price ratio, durable performance and competitive price.

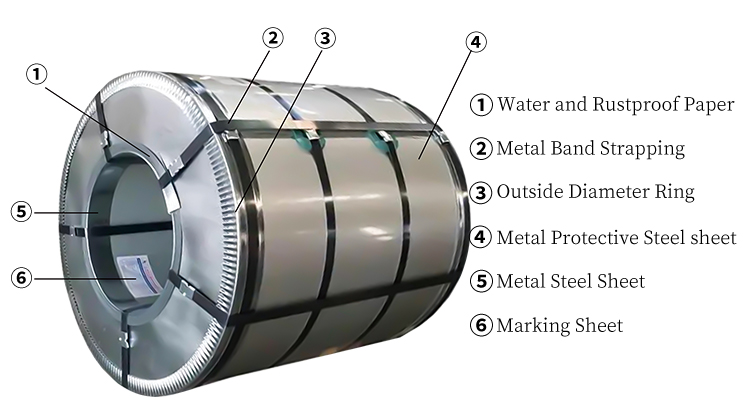

PPGI coils are based on hot-dip galvanized sheet, hot-dip aluminum-zinc sheet, electro-galvanized sheet, etc. After surface pre treatment (chemical degreasing and chemical conversion treatment), one or more layers of organic paint are applied on the surface, followed by The product is cured by baking. It is also named after the color steel coil plate coated with various colors of organic paint, referred to as color coated coil.

Color coated coil is hot galvanized plate, hot galvanized aluminum zinc plate, galvanized plate and other substrates, the surface pre-treatment (chemical degreasing and chemical conversion treatment), on the surface coated with a layer or several layers of organic coating, and then after baking curing products. Because coated with a variety of different colors of organic paint color steel coil plate named, referred to as color coated coil. The use of hot dip galvanized steel strip as the base material of color coating steel strip in addition to the zinc layer protection, the zinc layer of the organic coating to cover and protect the rust of the steel strip, the service life is longer than galvanized strip, about 1.5 times.

Our factory is large and well-equipped with modern production lines and advanced processing equipment. This allows us to achieve large-scale production while ensuring the quality and stable supply of our products. We pay attention to quality control at every stage, from raw material procurement to production process monitoring, to ensure that each roll of PPGI coil meets international standards and customer requirements.

Product quality has always been our factory’s top priority. We strictly adhere to international standards and quality management systems and conduct strict quality inspections and controls at each production stage. We use high-quality raw materials and employ advanced production processes to ensure our PPGI coils have excellent weather resistance, corrosion resistance, and coating adhesion. Our products have undergone rigorous testing and validation and can meet various application requirements such as construction, appliances, automobiles, and others.

Let’s start by discussing our impressive customization options. We take pride in offering an extensive range of colors for our PPGI coils. With our advanced color coating technology, we can deliver vibrant, long-lasting finishes in a plethora of shades. Whether you require bold and eye-catching colors or subtle and elegant tones, we have the expertise to fulfill your specific requirements.

Furthermore, our factory prioritizes precision and quality at every stage of the production process. From carefully selecting top-grade raw materials to implementing stringent quality control measures, we ensure that each PPGI coil meets international standards and surpasses customer expectations. Our commitment to excellence extends to durability, weather resistance, corrosion protection, and superior coating adhesion.

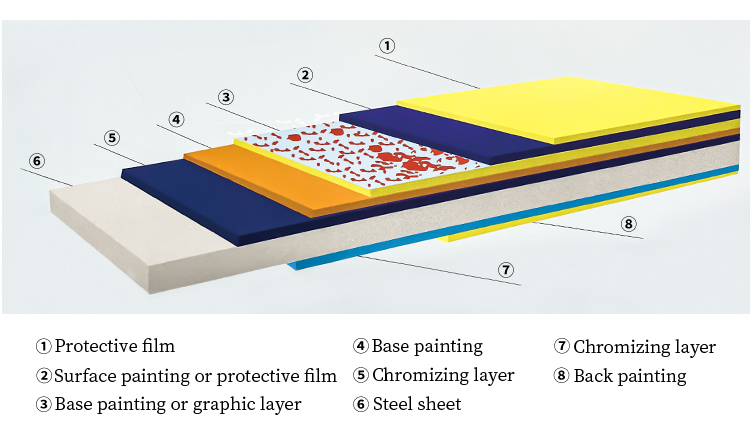

Structure of Prepainted Galvanized Steel Coils:

1. Topcoat (finishing) which provides color, pleasing appearance and appearance, and a barrier film to enhance long-term durability.

2. Primer coat to prevent undercutting of paint and enhance corrosion resistance.

3. Pretreatment layer applied for good adhesion and to enhance corrosion resistance.

4. Base steel sheet.

In addition, our highly skilled technical team plays a vital role in our factory’s success. Their deep industry knowledge and experience enable us to provide customized solutions tailored to your unique specifications. They work closely with clients, offering expert guidance throughout the design and production process. We value collaboration and strive to build long-term partnerships based on trust and satisfaction.

We appreciate your interest in our factory. If you have any questions or require further information about our customizable PPGI coil colors or any other aspect of our products and services, please do not hesitate to contact us. We look forward to the opportunity of working with you and delivering exceptional results.

Bright Color Category: Featured for bright and color diversity.

Excellent performance category:

Including PVDF,SMP,energy-saving color steel,self-cleaning color steel,anti-static color steel,antibiosis color steel etc..with excellent functional performance.They are used for large industrial plants and public buildings.

Originality category:

Developed by a special process and special paint. Product of originality category has special surface effects such as wrinkled plates, wooden grain plates, etc, which can meet the customized requirements.

The main material of color paint coating is PE paint, which has the characteristics of low price, various colors, and high-temperature resistance. The corrugated color-coated sheets coating is a product obtained by subjecting a galvanized steel sheet or galvalume steel sheet to a surface chemical treatment (roll coating) or a composite organic coating (such as a PVC coating) and then baking and curing.

Type of paint :

Polyester (PE)

Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance and low cost.

Silicon modified polyester

That is (SMP), the hardness, wear resistance and heat resistance of the film are good, as well as good external durability and pulverization resistance, gloss retention, general flexibility and medium cost.

High durability polyester

Namely (HDP), excellent color retention and UV resistance, excellent outdoor durability and pulverization resistance, good film adhesion, rich colors and excellent cost performance.

Polyvinylidene fluoride

Namely (PVDF), excellent color retention and UV resistance, excellent outdoor durability and pulverization resistance, excellent solvent resistance, good formability, dirt resistance, limited color and high cost.

Application:

It has strong durability, corrosion resistance, decoration, and formability. widely used in construction, household appliances, solar energy, transportation and other industries.