Common wire nails

common nails

wire nails

iron nails

wood nails

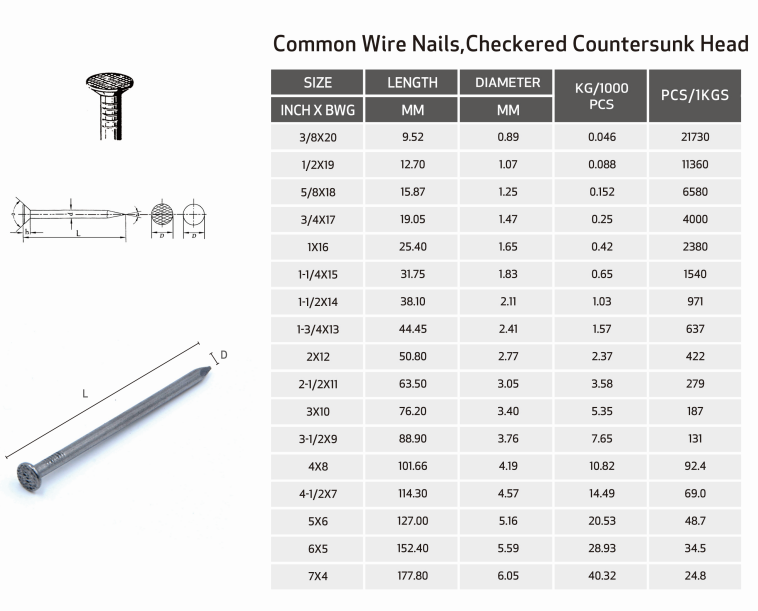

Common wire nails, iron nails, wood nails specification, and all kinds of packing.

Common Nails for Framing, Carpentry, and Construction

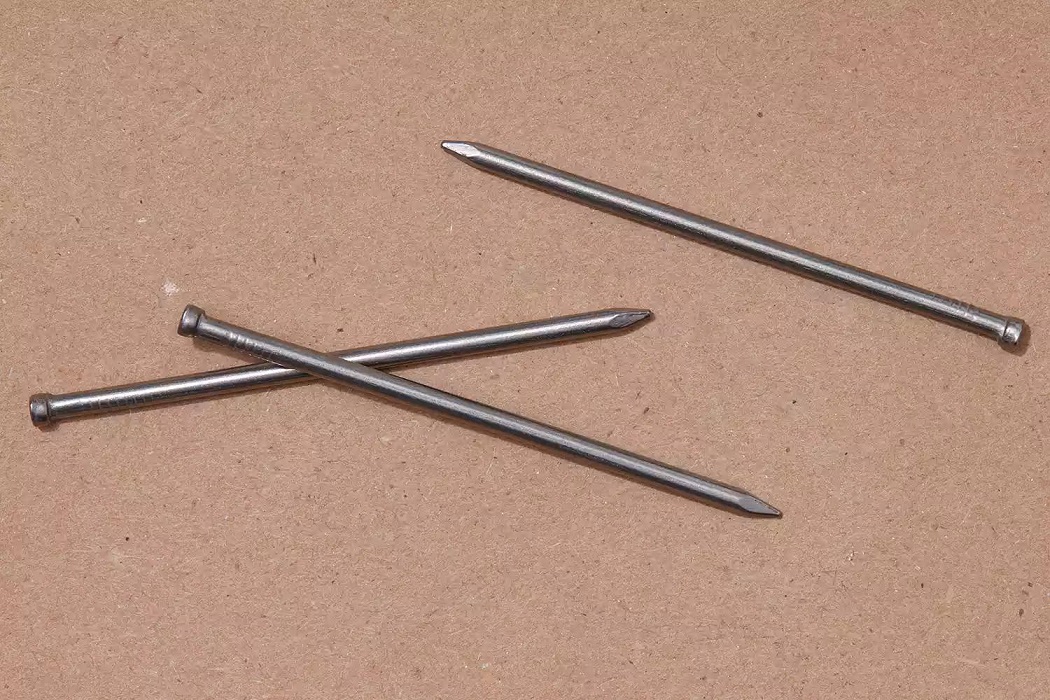

Common nails are the most commonly used type of steel nails. These nails have a thicker and larger shank than that of the box nails. In addition, common steel nails are also shown as a wide head, a smooth shank, and a diamond-shaped point. Workers like to use common nails for framing, carpentry, wood structural panel shear walls, and other general indoor construction projects. These nails range from 1 to 6 inches in length and 2d to 60d in size. For special uses, please take a moment to browse our website, here is a complete model of nails for you.

FEATURE

1. Most popular & versatile fasteners for indoor finishing.

2. Strong and stiff for medium & heavy projects.

3. Great holding power and resistance to bending.

4. Large & flat head can flush with the material’s surface.

5. Smooth shank for easy operation.

6. Complete gauges, lengths and sizes are available.

| Materials | Q195,Q235 iron wire rod or according to request |

| Finish | Polished ,galvanzied /E.g , Vinyl Coated (VC),or hot dipped galvanized /H.D.G |

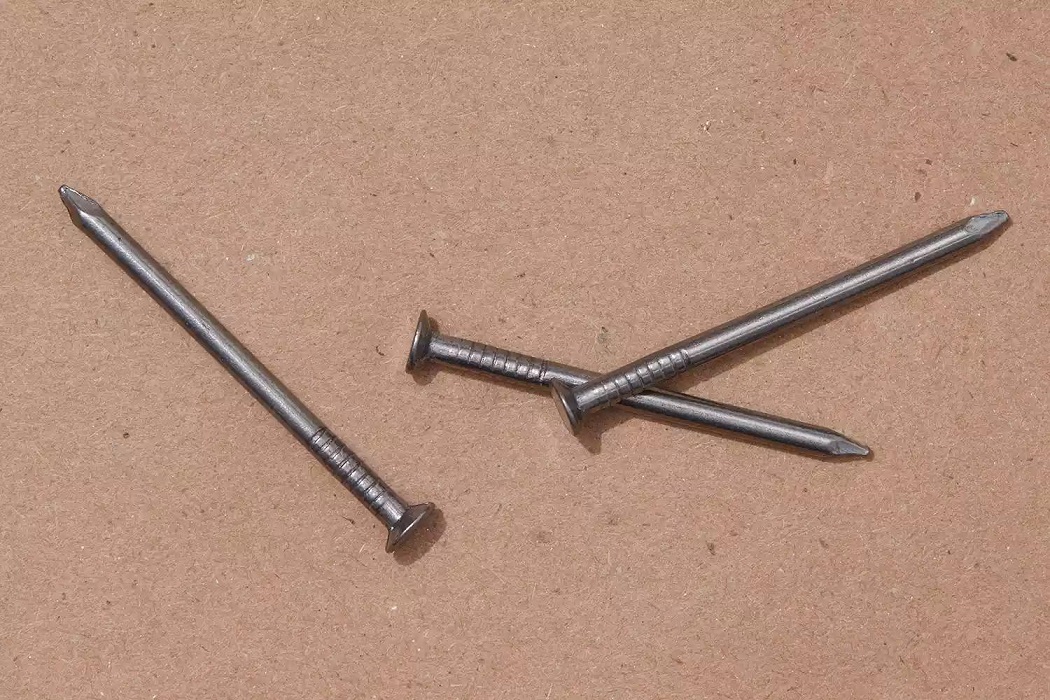

| Head | Countersunk checked head, flat head |

| Shank | Plain shank, Twisted Shank |

| Point | Diamond Point |

| Packing | box ,carton ,case , plastic bags ,etc . |

Understanding Nail Sizes and Basic Types

The hammer and nail. Like peanut butter and jelly, it’s a classic combination that has been around forever.

While a hammer and nail may seem as simple as it gets, do you know which nail to use in every application? Just as hammers require some knowledge for using them effectively, nails have right and wrong uses. The right nail has the right strength, size, and other design features for the job at hand. The wrong nail for the job can result in a weak connection and/or damage to the wood.

The physics of how nail works are simple. When driven into wood, the shaft of a nail pushes apart wood fibers as the point penetrates. The holding power of a nail derives from the simple friction of the displaced, bentwood fibers gripping the shaft of the nail. Nails are available in different sizes and shaft configurations to maximize their holding power in different applications.

Nail Materials

Nails can be made from a variety of metals, including ordinary steel, stainless steel, brass, copper, or aluminum. Or, nails can be galvanized or plated with zinc or another metal. Most construction nails are steel, often with some kind of surface coating. Many construction nails are coated with a thin layer of vinyl, which acts as a lubricant when driving the nail. Nails can also be coated with phosphate to improve their holding power. A nail that is uncoated in any way is often called a “bright” nail.

Nails intended for outdoor use are often galvanized or “hot-dipped” with a coating of zinc to improve their weather-resistance. Stainless steel is also used for outdoor applications, though stainless steel nails are considerably more expensive than zinc-plated nails. With pressure-treated lumber, it is essential that you use hot-dipped nails to prevent the corrosion caused by the chemicals used in the lumber.

How Nails are Sized

You’ve probably heard of nail sizes referred to as 10d, 16d, and so on. The number and “d” suffix are called the “Penny” system. The English penny used to be designated with a “d” representing the first letter of the Roman coin denarius. Originally, the penny number referred to the cost for 100 nails of a particular size. An 8d nail, for example, costs 8 pennies for 100.

Today, the penny system refers specifically to nail length. A 2d nail is 1 inch long, for example, while a 16d nail is 3 1/2 inches long. Each higher number in the penny system represents a 1/4-inch length increase, up to a 12d nail (3 1/4 inches long).

After the 12d nail, the penny system does not have a clearly defined relationship to length.

Common Nails

Common nails are used for general construction and specifically for framing and other structural work. They have a thick shank, a wide head, and a diamond-shaped point. They are most commonly used with 2 x dimensional lumber. Their thickness makes them strong but also more likely to split wood than when compared to thinner nails. Some carpenters actually dull the nail tip to prevent splitting the wood, though to do so means the tip will tear the wood fibers, thereby slightly reducing the holding power.

A special type of common nail is the sinker, which has a slightly narrower shank and a special head designed to be sunk flush with the surface of the wood.

Box Nails

Box nails are similar to common nails and sinkers but have thinner shanks and are better suited to thinner wood materials, such as 1x (3/4-inch-thick) lumber and exterior trim. Box nails should not be used for structural projects because they don’t have the strength and the holding power of common nails. The thinner shank of a box nail is less likely to split thinner materials.

Duplex Head Nails

Duplex head nails are specialty nails useful for temporary construction, such as formwork for pouring concrete or attaching temporary cleats during roofing work. You drive the nail until the lower head is flush with the wood. When it’s time to disassemble the project, you can extract the nail using the upper head and the claw of your hammer or pull bar.

Annular Ring or Ring Shank Nails

An annular ring also called ring shank, nails have rings on their shanks for extra grip and additional resistance to pulling out of the wood. They are commonly used for installing subflooring, where the extra holding power can help prevent floors from squeaking. Other nails that may have rings include drywall nails or deck board nails, also for improved holding power.

Masonry/ Concrete Nails

Masonry and concrete nails use hardened steel, often with longitudinal grooves along the length of the nail’s shaft to help them penetrate very hard materials by spiraling as they are driven. These nails are thick and very strong. They are designed to be fastened into concrete, concrete block, and mortar joints.

Casing/ Finish Nails

Casing and finishing nails are similar, differing primarily in the shapes of their heads. A finishing nail has a small, slightly rounded head that is just slightly bigger than the nail shank. The head is designed to accept the pointed tip of a nail set, making it easier to countersunk the nail without slipping and gouging the wood.

A casing nail essentially is a large finishing nail. It is often used in exterior applications, such as for installing exterior trim boards and for nailing door frames and trim. They are commonly galvanized for corrosion resistance. The nail head of a casing nail is tapered and may be set flush or just below the wood surface.

Brad Nails

Brad nails (or brads) are used in light finish woodworking and are essentially very small finishing nails. Because of the small shank diameter and the small head, these nails greatly reduce the possibility of splitting when used in hardwood. Brads are ideal for general joinery and are usually countersunk below the surface of the wood using a nail set—the holes are then filled with putty for a finished appearance.

Roofing Nails or Clout Nails

Roofing nails, sometimes called clout nails, have a short shank and a wide, flat, thin head. They can be used to fasten shingles, roofing felt, or sheet metal to wood. The shanks can be smooth or ringed for increased pull-out-resistance.