Yes, the weather resistance of PPGI (Pre-Painted Galvanized Iron) steel coils can help reduce construction costs. Here’s how:

Durability and Longevity

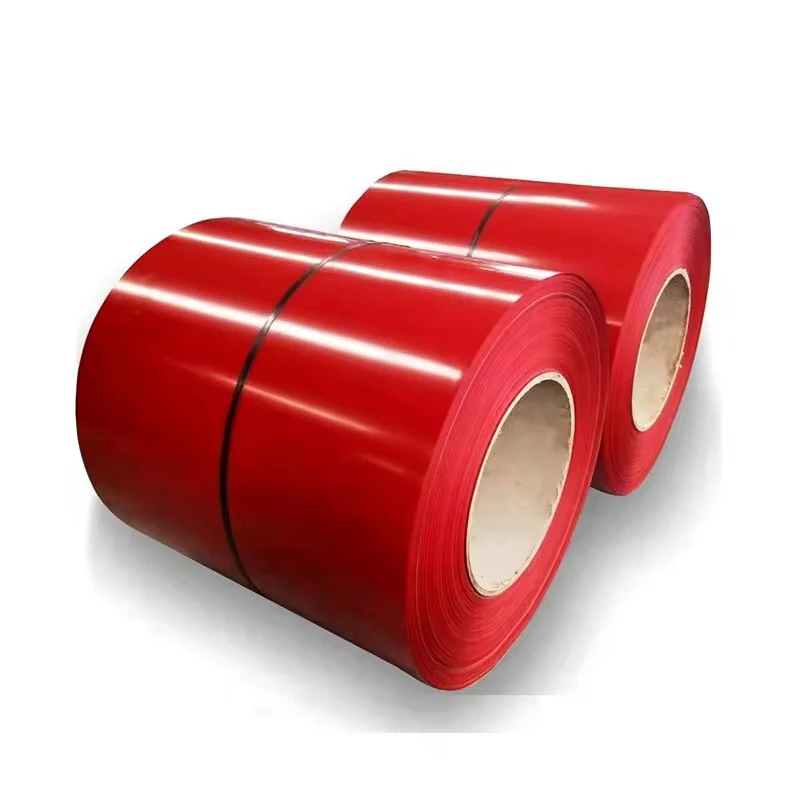

- Corrosion Resistance: PPGI steel coils are coated with a layer of zinc, followed by a primer and topcoat of paint, which offers superior protection against rust and corrosion. In environments with high humidity, coastal areas, or regions with acid rain, this resistance is crucial. By preventing rust, PPGI steel structures have a longer lifespan, reducing the need for replacements or major repairs over the building’s life cycle.

- Impact on Lifespan: Structures made from PPGI steel can last decades without significant deterioration. This longevity means that initial investments are protected, and the need for large-scale refurbishment is minimized.

Reduced Maintenance Costs

- Low Maintenance Requirements: The coating on PPGI steel coils is designed to be resistant to chipping, peeling, and fading. This reduces the frequency and cost of repainting or re-coating the surface, especially compared to other materials like bare metal or wood, which require regular upkeep.

- Savings on Repairs: Because the steel is protected from environmental factors that would typically cause wear and tear, the costs associated with repairing structural components due to weather damage are significantly lower.

Energy Efficiency

- Heat Reflectivity: Certain PPGI coatings are formulated to reflect solar radiation. This reflective property reduces the amount of heat absorbed by the building, leading to lower cooling costs, particularly in hot climates. This benefit can be further amplified by choosing lighter colors for the PPGI coils, as they reflect more sunlight.

- Thermal Insulation: PPGI steel coils can also be combined with insulation layers to enhance the building’s thermal performance. The weather-resistant coating ensures that the insulation remains effective by protecting it from moisture and UV degradation.

Lightweight Material

- Ease of Installation: PPGI steel coils are lighter than traditional materials like concrete or brick. This makes them easier to transport and handle on-site, reducing the time and labor required for installation. Faster installation not only lowers labor costs but also shortens the construction timeline, which can reduce overall project costs.

- Reduced Structural Support: Due to their lightweight nature, PPGI steel coils require less robust structural support compared to heavier materials. This can lead to savings in the cost of foundations and supporting frameworks.

Versatility

- Multiple Applications: PPGI steel coils can be used for various parts of a building, such as roofing, wall cladding, and even ceilings. This versatility means that a single material can meet multiple needs, simplifying logistics and potentially leading to bulk purchasing discounts.

- Design Flexibility: The wide range of colors, textures, and finishes available for PPGI steel allows for greater architectural freedom. This can enable more cost-effective designs without compromising on aesthetics or functionality.

Conclusion

The weather resistance of PPGI steel coils contributes significantly to reducing construction costs through multiple avenues:

- Lower maintenance and repair costs due to durability and resistance to environmental damage.

- Reduced energy expenses thanks to the material’s reflective properties and insulation capabilities.

- Savings in installation and structural support costs due to the material’s lightweight nature.

- Streamlined construction processes with the versatility of PPGI steel coils, enabling their use in various applications.

These factors make PPGI steel coils a cost-effective choice for both initial construction and long-term building management.