Introduction

In the construction industry, precision and consistency are critical to ensuring the safety, strength, and longevity of structures. One of the important standards for wire diameter measurement is A.S.W.G, which stands for American Steel Wire Gauge. It is a standardized system used to specify the diameter of steel wires, commonly applied in concrete reinforcement, structural frameworks, fences, pipelines, and many other construction applications.

Understanding A.S.W.G is essential for engineers, architects, material suppliers, and contractors to correctly select materials according to design specifications and performance requirements.

What is A.S.W.G?

A.S.W.G (American Steel Wire Gauge) is a traditional wire gauge standard developed in the United States in the 19th century. It defines the wire diameter size through a set of numerical codes. In the A.S.W.G system:

- The higher the gauge number, the smaller the wire diameter.

- The lower the gauge number, the larger the wire diameter.

For example:

- A.S.W.G No. 8 has a diameter of 0.1943 inches (about 4.93 mm).

- A.S.W.G No. 20 has a diameter of 0.0470 inches (about 1.19 mm).

This system helps unify manufacturing standards and improve communication efficiency between design, procurement, and construction teams.

Origins and Development

The A.S.W.G standard originated in the early industrial period of the United States, when steel wire production rapidly expanded for construction and manufacturing industries. Before standardized gauges were established, wire dimensions varied significantly between manufacturers, causing problems in quality control and engineering design.

The emergence of A.S.W.G effectively unified industry practices. Over time, it became one of the important reference systems alongside B.W.G (Birmingham Wire Gauge) and S.W.G (Standard Wire Gauge, British standard). Although today’s construction industry also uses metric units (millimeters) widely, A.S.W.G remains particularly influential in North America, South America, and regions influenced by American engineering standards.

A.S.W.G Wire Size Chart

Below is the full-size chart from A.S.W.G No.1 to No.30:

| A.S.W.G No. | Diameter (inches) | Diameter (mm) |

|---|---|---|

| 1 | 0.3065 | 7.78 |

| 2 | 0.2893 | 7.35 |

| 3 | 0.2720 | 6.91 |

| 4 | 0.2550 | 6.48 |

| 5 | 0.2391 | 6.07 |

| 6 | 0.2242 | 5.69 |

| 7 | 0.2092 | 5.31 |

| 8 | 0.1943 | 4.93 |

| 9 | 0.1794 | 4.56 |

| 10 | 0.1650 | 4.19 |

| 11 | 0.1495 | 3.80 |

| 12 | 0.1345 | 3.42 |

| 13 | 0.1205 | 3.06 |

| 14 | 0.1070 | 2.72 |

| 15 | 0.0950 | 2.41 |

| 16 | 0.0830 | 2.11 |

| 17 | 0.0720 | 1.83 |

| 18 | 0.0625 | 1.59 |

| 19 | 0.0540 | 1.37 |

| 20 | 0.0470 | 1.19 |

| 21 | 0.0410 | 1.04 |

| 22 | 0.0355 | 0.90 |

| 23 | 0.0315 | 0.80 |

| 24 | 0.0280 | 0.71 |

| 25 | 0.0250 | 0.64 |

| 26 | 0.0220 | 0.56 |

| 27 | 0.0200 | 0.51 |

| 28 | 0.0180 | 0.46 |

| 29 | 0.0165 | 0.42 |

| 30 | 0.0150 | 0.38 |

Note:

- The diameter decreases as the gauge number increases.

- Different industries and projects may adopt slightly adjusted values based on specific technical requirements.

Application of A.S.W.G in Construction

A.S.W.G steel wires are extensively used in the following construction fields:

5.1 Concrete Reinforcement

- Steel Meshes: Wires of specific A.S.W.G gauges are welded into meshes to reinforce concrete slabs, beams, columns, and walls.

- Example: A.S.W.G #8 or #10 is often used for reinforced concrete wall construction.

5.2 Structural Supports

- Frameworks: Used in prefabricated buildings, suspended ceilings, and lightweight steel structures.

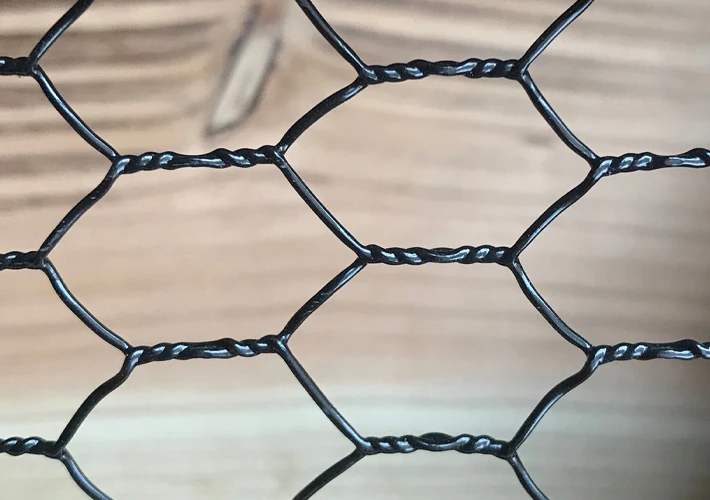

5.3 Fencing and Barriers

- Construction Site Safety Fences: Wires between A.S.W.G #10 and #16 are commonly used.

- Boundary Barriers: Durable fencing solutions for commercial, industrial, and residential areas.

5.4 Plumbing and Mechanical Systems

- Wire Reinforced Hose: Wire of specific gauges is embedded in hoses to resist pressure.

- Pipe Wall Measurement: Some pipe wall thickness specifications are referenced with wire gauge equivalents.

5.5 Specialty Applications

- Suspension Systems: For hanging lighting, ceilings, or mechanical equipment.

- Formwork Tying: Tying reinforcement bars or forms in reinforced concrete work.

Why Is A.S.W.G Important?

(1) Standardization and Precision:

The A.S.W.G system ensures precise communication of wire sizes, reducing errors in design, procurement, and construction.

(2) Wide Industrial Acceptance:

Especially in regions where U.S. engineering systems are adopted, A.S.W.G is a common technical language across manufacturers and builders.

(3) Easy Selection and Design:

Engineers can quickly determine tensile strength, load-bearing capacity, and other mechanical properties based on A.S.W.G size.

(4) Quality Control:

Production and inspection processes are easier to standardize when using clear and recognized wire gauge standards.

A Practical Example: Construction Wall Reinforcement Using A.S.W.G

Below is a simple illustration showing how A.S.W.G wire is used in a concrete wall:

┌──────────────────────────────┐

│ │

│ Building Wall (Steel Mesh) │

│ │

│ ┌───────┐ ┌───────┐ │

│ │ A.S.W.G #8 │───│ A.S.W.G #10│─── (Steel Mesh) │

│ └───────┘ └───────┘ │

│ │

│ Concrete Pouring │

│ │

└──────────────────────────────┘

Explanation:

- A.S.W.G #8 and A.S.W.G #10 wires are welded into a mesh to serve as the reinforcing layer inside the wall.

- This enhances the wall’s tensile strength, crack resistance, and overall structural integrity.

Differences Between A.S.W.G, B.W.G, and S.W.G

| Standard | Full Name | Main Region | Characteristics |

|---|---|---|---|

| A.S.W.G | American Steel Wire Gauge | USA, Americas | Focused on steel wires |

| B.W.G | Birmingham Wire Gauge | UK, Commonwealth countries | Older system, mainly for pipes |

| S.W.G | Standard Wire Gauge | UK | Used for general wires and electrical wires |

Although they all use “gauge numbers,” the actual diameters differ, so they cannot be directly interchanged without conversion.

Conclusion

A.S.W.G (American Steel Wire Gauge) is a crucial sizing system in the construction industry, providing a reliable basis for the selection and application of steel wires. From concrete reinforcement to fencing and mechanical systems, A.S.W.G ensures project quality and efficiency.

Understanding A.S.W.G not only helps professionals better grasp project requirements but also promotes accurate communication among different stages of construction, procurement, and inspection.

In today’s international engineering projects, although metric standards are becoming increasingly popular, A.S.W.G still holds its irreplaceable position in many projects — particularly in North America, Latin America, and other regions that closely follow U.S. technical standards.