Color steel sheets, also known as pre-painted steel sheets, undergo several processing techniques to achieve their desired characteristics and applications. These techniques can be broadly categorized into the following steps:

1. Surface Preparation

- Cleaning: The steel sheet is cleaned to remove dirt, oil, and other contaminants. This is typically done using a combination of chemical degreasers and hot water.

- Rinsing: After cleaning, the sheet is rinsed to remove any residual cleaning agents.

- Surface Treatment: The sheet undergoes surface treatments such as phosphating or chromating to enhance corrosion resistance and improve paint adhesion.

2. Coating Application

- Primer Coating: A primer layer is applied to the prepared surface to improve adhesion of the top coat and provide additional corrosion protection. This is often done using a roll coating technique.

- Curing: The primer is then cured by passing the sheet through an oven to dry and harden the coating.

- Top Coating: The topcoat, which provides the final color and appearance, is applied over the cured primer. The type of topcoat used depends on the desired properties of the finished product (e.g., polyester, silicone-modified polyester, polyvinylidene fluoride (PVDF), or plastisol).

- Final Curing: The topcoat is also cured in an oven, ensuring a durable and uniform finish.

3. Post-Coating Treatments

- Cooling: After curing, the coated sheet is cooled down to room temperature using air or water cooling methods.

- Leveling: The sheet is passed through leveling machines to ensure flatness and uniform thickness.

- Protective Film Application: A protective film may be applied to the surface to prevent damage during handling and transportation.

4. Cutting and Shaping

- Cutting: The coated steel sheet is cut into desired sizes and shapes using techniques such as shearing, slitting, or laser cutting.

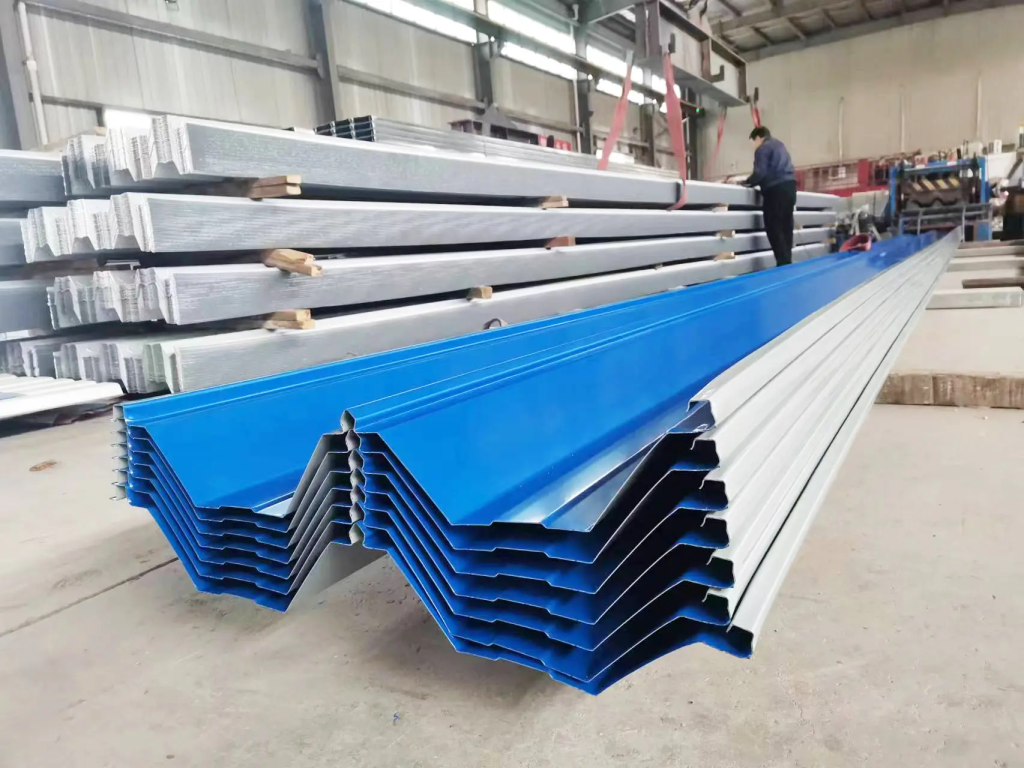

- Shaping/Forming: Depending on the application, the sheets may undergo additional forming processes such as roll forming, bending, or stamping to achieve the required profiles and structures.

5. Quality Control

- Inspection: Throughout the entire process, the sheets are inspected for defects such as coating thickness, adhesion, color consistency, and surface finish.

- Testing: Various tests, including mechanical, chemical, and environmental tests, are conducted to ensure the sheets meet the required specifications and standards.

6. Packaging

- Wrapping: The sheets are wrapped in protective materials to prevent damage during shipping.

- Bundling: The sheets are bundled together, often using steel straps, for easy handling and transportation.

These processing techniques ensure that color steel sheets are not only visually appealing but also possess the necessary durability, corrosion resistance, and mechanical properties for their intended applications in construction, automotive, appliances, and other industries.

If you want to get the latest colors of color steel sheets, please contact us!