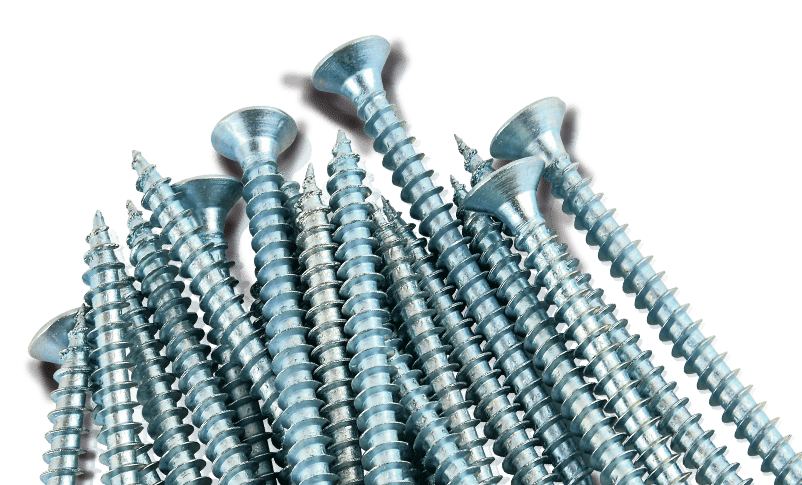

Drywall screws, known for their sharp points and threads designed for fastening drywall to wood or metal studs, are widely used in construction and DIY projects. Here are the applications and future development trends of drywall screws:

Applications of Drywall Screws in Daily Life

- Drywall Installation:

- Primary Use: Drywall screws are primarily used to attach drywall sheets to wooden or metal studs. They provide the necessary hold to keep the drywall securely in place and prevent it from sagging or detaching over time.

- Ceiling Installation: Special screws with higher holding power are used for ceilings to counteract gravity.

- Soundproofing and Insulation: When adding additional layers of drywall for soundproofing or insulation, these screws are essential to secure the multiple layers.

- General Construction:

- Framing: Besides drywall, these screws can be used in light framing tasks, especially in residential construction where the use of wood is prevalent.

- Subflooring: In the construction of floors, drywall screws help secure plywood or other subfloor materials to the wooden or metal frame, ensuring stability and preventing squeaking.

- Furniture Assembly:

- DIY Furniture: Drywall screws are popular in DIY furniture projects due to their ease of use and strong hold. They are often used in the construction of bookshelves, tables, and other wooden furniture.

- Professional Manufacturing: In the mass production of flat-pack furniture, these screws are used to assemble components quickly and securely.

- Home Repairs and Maintenance:

- Fixing Loose Drywall: When drywall panels start to come loose, drywall screws can be used to reattach them securely without the need for extensive repairs.

- Attaching Fixtures: Installing shelves, hooks, brackets, and other fixtures to walls often requires the use of drywall screws for a secure and lasting hold.

- Crafts and Hobbies:

- Woodworking: Hobbyists and craftsmen use drywall screws in various woodworking projects for their ease of use and strong holding capability.

- Model Building: In larger-scale model building, drywall screws can provide the necessary strength to hold components together.

Future Development Trends

- Material Innovations:

- Advanced Alloys and Coatings: Future screws might be made from high-strength alloys or feature advanced coatings like ceramic or polymer coatings to enhance their corrosion resistance, making them suitable for exterior applications or humid environments.

- Composite Materials: Development of screws using composite materials that combine strength, lightweight properties, and resistance to environmental degradation.

- Sustainability:

- Eco-friendly Manufacturing: Companies are focusing on reducing the carbon footprint of manufacturing processes. This includes using recycled materials and implementing energy-efficient production techniques.

- Biodegradable Screws: Research into screws made from biodegradable materials that can decompose without harming the environment after their useful life.

- Enhanced Design and Efficiency:

- Optimized Thread Design: Improved thread patterns that allow screws to be driven faster and with less effort while providing a stronger hold. This can include variable thread depths or dual-thread designs.

- Self-drilling Tips: Incorporation of tips that can drill into the material without needing a pilot hole, making the installation process quicker and reducing the need for additional tools.

- Specialized Applications:

- Multi-material Compatibility: Screws designed to work effectively with a broader range of materials, including new construction materials like fiber cement and engineered wood products.

- High-performance Screws: Screws designed to meet specific requirements such as fire resistance, which is crucial in certain building codes and standards for safety.

- Automation and Technology Integration:

- Smart Fasteners: Screws embedded with RFID chips or other tracking technologies that allow for better inventory management, quality control, and verification in large construction projects.

- Automated Tools: Development of automated screw-driving systems that can speed up the installation process, ensure consistent screw placement, and reduce manual labor.

- Ergonomics and User Convenience:

- Improved Screw Design: Innovations in the physical design of screws to make them easier to handle and drive. This includes ergonomic head designs that fit better with screwdrivers and power tools.

- Packaging Innovations: Packaging solutions that make it easier to access and organize screws, such as resealable packs, compartmentalized boxes, and clear labeling for quick identification.

Conclusion

Drywall screws are indispensable in modern construction and DIY projects due to their versatility, strength, and ease of use. The future trends in the development of drywall screws aim to enhance their performance, sustainability, and user convenience. Innovations in materials, design, and technology integration will likely make these fasteners even more efficient and eco-friendly, meeting the evolving needs of the construction industry and everyday users.